- Home

- »

- Mono Solar Panel

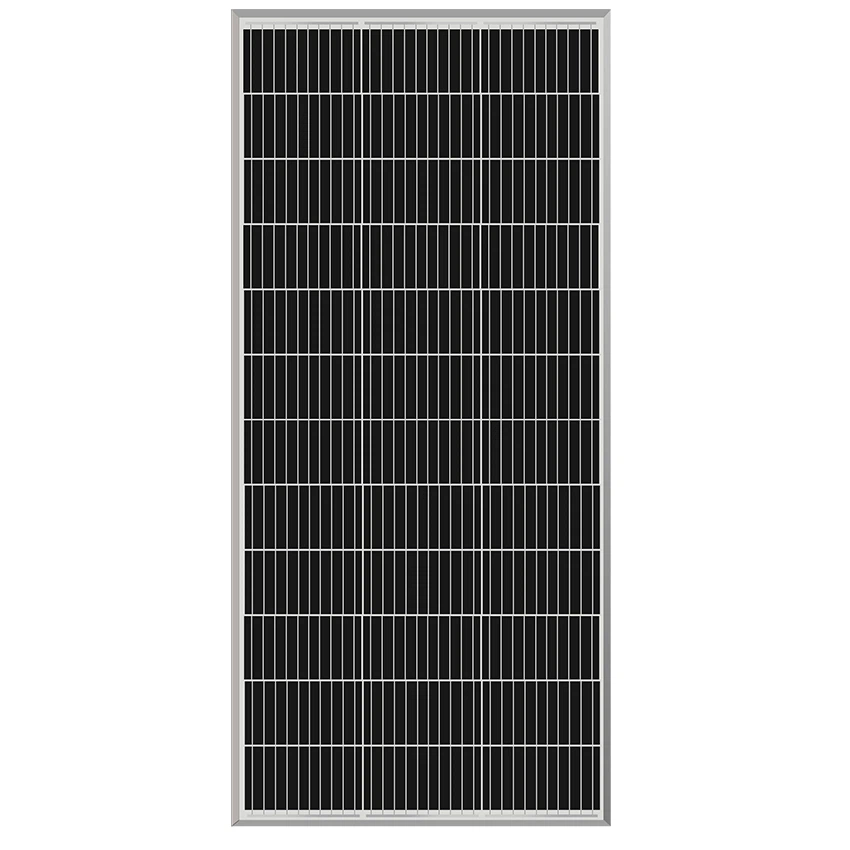

Mono Solar Panel

Categories

Solar Panel

Solar Power System

Solar Cell

Hot products

Your leading supplier of Baoding Dongliang New Energy Technology Co., Ltd

Baoding Dongliang New Energy Technology Co., Ltd. is a high-tech enterprise focusing on the integrated application of photovoltaic products, committed to the design, research and development, production and sales of photovoltaic panels, solar power generation systems and other products.

Why Choose Us?

01/

Quality

We provide our customers with high-quality products, and we have applied for IEC, CE, ISO and other related certifications for our products.

02/

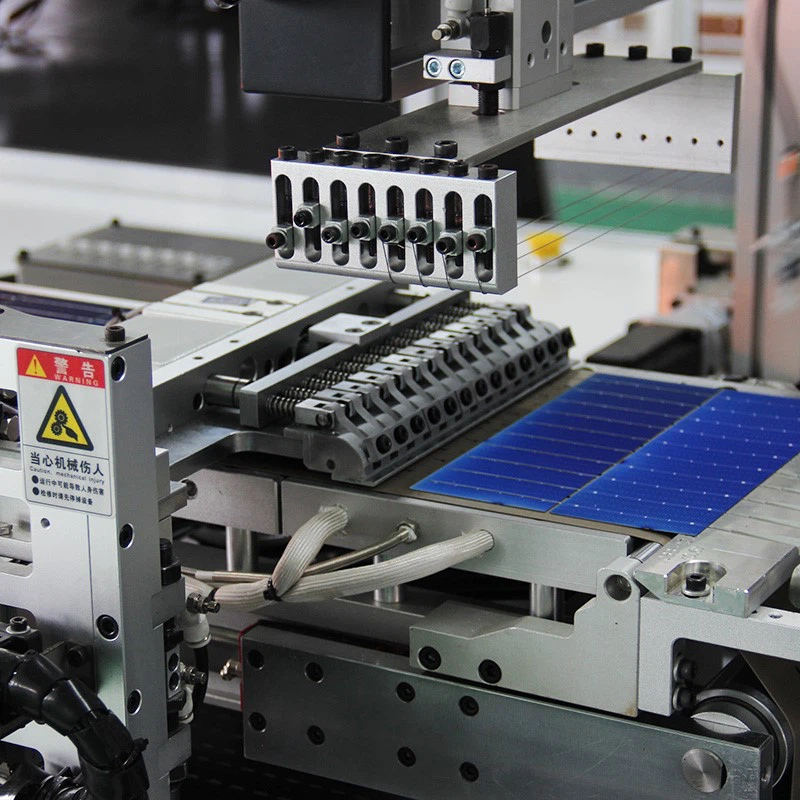

State-of-the-art equipment

We have 1 SMT production line, 2 photovoltaic production lines, 1 lithium battery pack line and other modern production lines.

03/

With 11 years of experience, we can develop, produce and sell any new energy-related products, modules, inverters, controllers, batteries, brackets, cables and other complete solutions according to your needs;

04/

The company has enough practice in the application of photovoltaic-related products, including grid-connected photovoltaic power generation, off-grid photovoltaic power generation, BIPV projects, wind-solar complementary projects, and application-oriented power supply systems (monitoring power supply, sensor power supply, solar street lights, etc.);

What is Mono Solar Panel?

Monocrystalline solar panels are characterized by their black PV cells with rounded edges. They have a higher conversion efficiency than polycrystalline panels, which means they produce more kilowatt-hours of electricity. If you want to install a solar panel system but your space is limited, monocrystalline panels will be more productive per square foot. While they’re the most efficient solar panels, they’re also the most expensive, since the manufacturing process of single-crystal silicon cells is more complex.

Benefits of Mono Solar Panel

Space efficient

These solar panels are economical when it comes to saving space. They are generally smaller, allowing them to fit even in the most limited roof spaces or locations and still work efficiently.

High power efficiency and performance

Monocrystalline solar panels have higher power efficiency and performance output than other solar panels. The efficiency often ranges from 15% to 24% resulting from its ability and ease to allow the free flow of electrons and electric currents.

Longer lifespan

These solar panels have a long lifespan and are the oldest form of solar panels which still exist and perform exceptionally in the world today. Most of the early models installed in previous decades are still working today, giving homeowners confidence in their longevity, and will not have the stress and incur costs in replacing them sooner.

Affordable installation costs

The costs of installing these solar panels are relatively lower than others. They do not require complicated installation processes and much time compared to thin film panels when installing. This gives it an edge when installation costs are considered in acquiring solar panels.

Greater heat resistance

High heat levels affect most solar panels’ output, reducing their efficiency. However, the monocrystalline panels have a more excellent heat resistance, reducing the efficiency loss rate resulting from increased heat levels.

More electricity

The monocrystalline panels produce high quantities of electricity per square meter, reducing the need to install other electricity sources, such as fossil fuels which are environmental hazards. The high amount of electricity also reduces the bulkiness of installing several solar panels to produce the same quantity.

Application of Mono Solar Panel

1.Monocrystalline solar panels are used in locations with less sunlight.

2.They have smaller applications

3.They are more efficient but pricey

Since they produce more electricity on a smaller scale than polycrystalline solar panels, monocrystalline solar panels are ideal for locations with limited space. Even in locations with less sunlight, monocrystalline solar panels can capture the highest amount of energy. They are perfect if you are looking for efficient solar panels and the cost is not your primary concern.

Although all solar panels are large, monocrystalline panels blend into the background more effectively than poly units due to their dark color.

Compared to polycrystalline panels, monocrystalline solar panels offer superior heat tolerance. Monocrystalline panels are a wise choice for you if you are residing in a hot climate like a desert.

Components of Mono Solar Panel

Backsheet

Operating inconspicuously behind the solar panel is the back sheet layer, a seemingly silent, yet vital solar panel part that shields the panel from external elements.

Placed on the panel’s rear, it is employed as a formidable guard against shifting temperatures, the onslaught of UV rays, and moisture. The back sheet, formed from stalwartly defiant materials, assures the maintenance and protection of the internal components throughout the solar panel’s life span. It serves as the knight in shining armor, shielding against moisture that could potentially lead to electrical hiccups and efficiency loss.

Junction box and wiring

Though its presence might initially seem small, the junction box institutes a substantial function within the solar panel’s connectivity blueprint. Tucked away at the panel’s back, this mini box yields a sophisticated network of wiring that binds the photovoltaic cells together. It stands as an efficient junction platform for these connections, allowing a seamless transfer of the generated power.

In many cases, junction boxes are equipped with bypass diodes that regulate electrical flow and minimize losses due to shadowing, thus playing a pivotal role in controlling the panel’s power delivery to the external grid.

Frame and mounting structure

Often overlooked and underappreciated, the frame of a solar panel stands as a foundational pillar, providing both structural integrity and facilitating seamless installation. Crafted from robust materials such as aluminum, the frame not only imparts robustness to the panel but also doubles as a mounting apparatus.

This essential feature enables the secure fixation of solar panels onto a variety of surfaces, spanning from residential rooftops to expansive ground installations. The enduring nature of the frame ensures the panel’s longevity, enabling it to withstand the rigors of time and environmental conditions, all while preserving its efficiency and dependability throughout its operational lifespan.

EVA encapsulation and tempered glass

Glistening atop the surface of photovoltaic cells is a dynamic alliance of EVA (ethylene-vinyl acetate) encapsulation and tempered glass. This dynamic duo is designed with a dual purpose: protection and performance enhancement.

EVA encapsulation acts as a vigilant shield, guarding the delicate PV cells against mechanical abrasions, moisture, and particulate intrusion, all while facilitating the unhindered entry of sunlight. Overlaying the EVA is the fortified tempered glass, serving as a resolute, transparent barrier against unpredictable weather variations, relentless UV exposure, and external stresses. This synergistic defense mechanism secures optimal panel performance and extends its lifespan by safeguarding its core components.

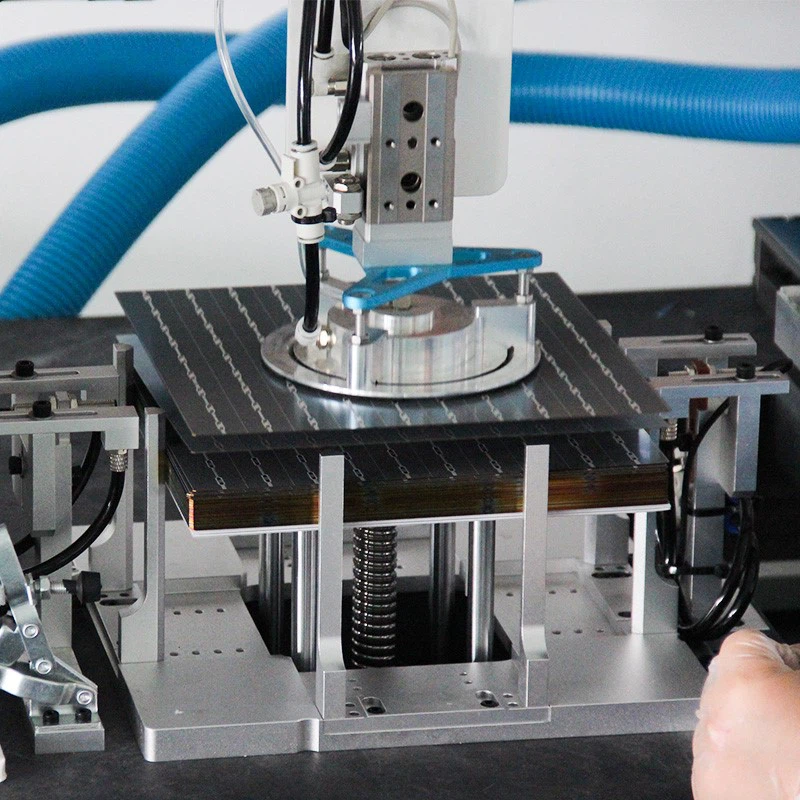

Process of Mono Solar Panel

Sand

It all starts with the raw material, which in our case is sand. Most solar panels are made of silicon, which is the main component in natural beach sand.

Silicon is abundantly available, making it the second most available element on Earth.

However, converting sand into high grade silicon comes at a high cost and is an energy intensive process. High-purity silicon is produced from quartz sand in an arc furnace at very high temperatures.

Ingots

The silicon is collected, usually in the form of solid rocks. Hundreds of these rocks are being melted together at very high temperatures in order to form ingots in the shape of a cylinder. To reach the desired shape, a steel, cylindrical furnace is used.

In the process of melting, attention is given so that all atoms are perfectly aligned in the desired structure and orientation. Boron is added to the process, which will give the silicone positive electrical polarity.

Mono crystalline cells are manufactured from a single crystal of silicon. Mono Silicon has higher efficiency in converting solar energy into electricity, therefore the price of monocrystalline panels is higher.

Wafers

Wafers represent the next step in the manufacturing process.

The silicon ingot is sliced into thin disks, also called wafers. A wire saw is used for precision cutting. The thinness of the wafer is similar to that of a piece of paper.

Because pure silicon is shiny, it can reflect the sunlight. To reduce the amount of sunlight lost, an anti-reflective coating is put on the silicon wafer.

Solar cells

The following processes will convert a wafer into a solar cell capable of converting solar power into electricity.

Each of the wafers is being treated and metal conductors are added on each surface. The conductors give the wafer a grid-like matrix on the surface. This will ensure the conversion of solar energy into electricity. The coating will facilitate the absorption of sunlight, rather than reflecting it.

In an oven-like chamber, phosphorous is being diffused in a thin layer over the surface of the wafers. This will charge the surface with a negative electrical orientation. The combination of boron and phosphorous will give the positive – negative junction, which is critical for the proper function of the PV cell.

From solar cell to solar panel

The solar cells are soldered together, using metal connectors to link the cells. Solar panels are made of solar cells integrated together in a matrix-like structure.

After the cells are put together, a thin layer (about 6-7 mm) of glass is added on the front side, facing the sun. The backsheet is made from highly durable, polymer-based material. This will prevent water, soil, and other materials from entering the panel from the back. Subsequently, the junction box is added, in order to enable connections inside the module.

It all comes together once the frame is assembled. The frame will also provide protection against impact and weather. The use of a frame will also allow the mounting of the panel in a variety of ways, for example with mounting clamps.

EVA (ethylene vinyl acetate) is the glue that binds everything together. It is very important that the quality of the encapsulant is high so it doesn’t damage the cells under harsh weather conditions.

Testing the modules

Once the module is ready, testing is carried out to ensure the cells perform as expected. STC (Standard Test Conditions) are used as a reference point. The panel is put in a flash tester at the manufacturing facility. The tester will deliver the equivalent of 1000W/m2 irradiance, 25°C cell temperature and an air mass of 1.5g. Electrical parameters are written down and you can find these results on the technical specification sheet of every panel. The ratings will reveal the power output, efficiency, voltage, current, impact and temperature tolerance.

Cleaning and inspection are the final steps of the production before the module is ready to be shipped to homes or businesses.

How to Maintain Mono Solar Panel

Dirt, debris, dust and other items can dirty solar panels and if the accumulation grows too much, it can start to impact the amount of energy that the solar panels produce. Be sure to turn your solar power system off prior to cleaning. Cleaning solar panels by spraying them down with lukewarm water from a hose usually does the trick. Do not use cleaning agents or soap to clean solar panels because they can leave streaks and damage the panels.

For solar panels with heavier deposits, spraying them down with a lukewarm water from a garden hose and wiping them down with a non-abrasive, microfiber cloth can get them clean. If you clean them while on a roof, remember to do so safely by using a safety harness to prevent falls. If cleaning from a ladder, use caution to prevent falls. Best yet, a telescopic pole with a microfiber cloth attached to it can help you safely clean solar panels from the ground.

TIP: Do not clean your solar panels on a sunny day because it can leave smudges since the water can evaporate quickly.

Cleaning solar panels in winter

Sometimes snow and ice can accumulate on solar panels but since they’re angled, it usually melts and slides off. Should snow or ice persist, spraying panels with lukewarm water can help remove it.

Avoid using hot water to clean snow and ice from solar panels because the temperature discrepancy can cause the panels to crack. You can also brush the panels off with something non-abrasive to prevent scratches.

How do Monocrystalline Solar Panels Work?

Monocrystalline solar panels transform sunlight into electrical energy using monocrystalline silicon cells, which are the most effective type of solar cell. These cells are produced by cutting a single silicon crystal into thin wafers.

When the sun’s rays fall on the solar panel, the photons in the light connect with the silicon atoms in the solar cell, causing electrons to break free from their atoms. These electrons circulate through the cell and are gathered by a wire circuit. This flow of electrons generates an electrical current that can power electrical devices or be stored in a battery for later use.

The efficiency of monocrystalline solar panels is due to the purity of the silicon used in their manufacture. Monocrystalline silicon has a more uniform structure than other silicon types, allowing for better electron flow through the solar cell. This results in a higher power output per square foot of solar panel compared to other types of solar panels.

How to Clean Solar Panels

Water: Using pure and high-quality water, preferably distilled or deionized, is recommended to avoid the formation of mineral stains or deposits on the surface of the solar panels.

Detergent: Mild detergents are compatible with the materials used in the panels such as glass and protective coatings. Specific detergents for PV panels can also be used. Harsh chemicals such as abrasive cleaners or solvents should be avoided as they may corrode the materials, scratch the photovoltaic cells, or leave residue.

Brushes, sponges, and cleaning tools: Soft bristle brushes can be used to remove dirt from solar panels. Try not to press too hard to avoid scratching or damaging the surface. If you use sponges or cloths, choose microfiber as they remove dirt and debris without damaging the surface of the solar panels.

Extendable handle: PV installations are usually located on roofs, so it’s convenient to use a telescopic pole or extendable handle to reach higher and more difficult areas. Safety is key to prevent possible accidents. If you can’t clean the solar panels yourself, hiring a specialized professional service is recommended.

How Are Solar Panels Recycled?

1.We remove the junction box and the frame mechanically.

2.We separate the silicon wafers from the glass and the plastic film. That’s done using heat or chemicals and some mechanical processing.

3.We use electricity and chemicals to separate and purify the different metals from the silicon wafers.

Silicon, plastics, glass, and metals are all recovered in solar panel recycling. Manufacturers can reuse them to make new solar panels and other items. It keeps waste out of the landfill and reduces the number of raw materials needed to create new products. Recycled silicon is used to make new silicon wafers.

Our Factory

At present, the company has more than 200 employees, including 20 R & D technicians, and has more than 10,000 production workshops, 1 SMT production line, 3 photovoltaic production lines, 2 lithium battery pack line and other modern production lines. The annual production capacity of photovoltaic modules reaches 15 megawatts.

Our Certificate

FAQ

Q: How does a mono solar panel work?

A: Monocrystalline PV panels are made from a single piece of silicon, therefore making it easier for electricity to flow through. They have a pyramid cell pattern which offers a larger surface area enabling monocrystalline PV panels to collect a greater amount of energy from the sun’s rays.

Q: Do mono solar panels work on cloudy days?

A: Monocrystalline solar panels are particularly effective in low-light conditions, such as on cloudy days, due to their strong electron mobility, enabling them to generate electricity efficiently even in weak illumination.

Q: What time do solar panels start charging?

A: The time of day when solar panels begin to generate electricity depends on various factors, such as location, weather conditions, and the position of the sun in the sky. Morning Sunlight: In the morning, solar panels start working as soon as there is enough sunlight to trigger the photovoltaic process.

Q: What time of day do solar panels work best?

A: Between 9am – 3pm

The best time of day to use solar-generated electricity is during the middle of the day when the sun is the strongest, usually between 9am – 3pm. These peak times can vary depending on the orientation and tilt of your panels but also where you live and the time of year.

Q: How do I know if my solar panel is charging?

A: Many solar panel systems come with built-in indicator lights to display the charging status. Check if the indicator light on your solar panels is lit, which usually indicates that the panels are receiving sunlight and charging your batteries.

Q: What happens when there is no sun for solar panels?

A: Your solar panel will technically always be functioning, but you won’t be getting any electricity without some form of sunlight. The only way to power your home with solar energy at night is to install a solar storage system, like a solar battery. Solar panels won’t generate much electricity under the stars.

Q: Do solar panels need maintenance?

A: Solar panels only need maintenance two to four times a year, but check your solar companies manual for panel specific maintenance care. Fall and spring serve as good times to perform maintenance work because panels can need cleaning following winter where dust and debris can accumulate.

Q: Do solar panels stop charging when battery is full?

A: When the battery is full, the excess power is directed back into the solar panels, resulting in a temporary increase in voltage. This method effectively reduces the overall efficiency of the system because the excess energy is essentially lost.

Q: How do I know if my solar panels are turned on?

A: A simple way to check on the health of your system is to look at the colour of the lights shining on the box on a sunny day, when the system should be busily generating solar power. A green light on your inverter means your system is functioning properly.

Q: Are mono solar panels any good?

A: Monocrystalline solar panels are best for areas where space is limited since they produce more electricity on a smaller scale than poly panels. Monocrystalline solar panels can draw out the maximum amount of energy even in areas of lower sunlight. So, they are ideal when the goal is efficiency more than cost.

Q: What is the difference between mono and mono perc solar panel?

A: Firstly, let us clarify on the PERC part of the name. Mono PERC solar cells are nothing but Mono crystalline solar cells but have additional reflective layer below them to allow the light which is not captured by the solar cells in first go, to have additional chance to capture it to convert it into electricity.

Q: How long do mono solar panels last?

A: Monocrystalline solar panels

They are easily identifiable by their black colour. On average, they are expected to last 25-30 years, but newer mono panels can last up to 40 years or longer.

Q: How do I know if my solar panel is monocrystalline?

A: Polycrystalline solar panels have blue cells made of multiple silicon crystals, and they are less efficient but more affordable. Monocrystalline panels have black cells made of single crystals, and they offer a higher efficiency at a higher price.

Q: Do solar panels age if not used?

A: All solar panels slowly degrade over time, which means they’re producing less electricity from the same amount of sunlight. How and why does this happen? Various external factors (like weather) wear down on the panels and negatively impact their ability to produce electricity.

Q: What is a monocrystalline solar panel made of?

A: A monocrystalline solar cell is fabricated using single crystals of silicon by a procedure named as Czochralski progress. Its efficiency of the monocrystalline lies between 15% and 20%. It is cylindrical in shape made up of silicon ingots.

Q: Why are monocrystalline solar panels black?

A: Monocrystalline Silicon Makes Solar Panels Black

During the production process, the silicon arranges itself in a single direction to form one large crystal. Because of this arrangement, the light interacting with the monocrystalline cells appears black to the human eye.

Q: Do monocrystalline solar panels need direct sunlight?

A: This is due to their high efficiency and the quality of silicon used in their construction. Monocrystalline solar panels can still produce large amounts of electricity even in indirect or diffuse sunlight, making them a reliable choice in areas where climate change or shading is an issue.

Q: Which is better monocrystalline or photovoltaic?

A: Monocrystalline Panels

These wafers are then formed into photovoltaic cells and inserted into the panel modules. Using single crystals provides higher efficiency than other solar panels, resulting in better power production for your home.

Q: Which solar panel has the highest efficiency?

A: Monocrystalline solar panels

Monocrystalline solar panels are the most efficient, with 15% to 22% real-world efficiency ratings at a higher price range. Polycrystalline panels are more affordable but only provide 12% to 17% efficiency.

Q: Do solar panels start working immediately?

A: The reality, though, is that at least a few, if not several, months are likely to pass between the moment you decide you’re serious about getting solar and when electrons start flowing through your system.

As one of the most professional mono solar panel manufacturers in China, we’re featured by quality products and good service. Please rest assured to buy customized mono solar panel made in China here from our factory.